The bare minimum is the best choice.

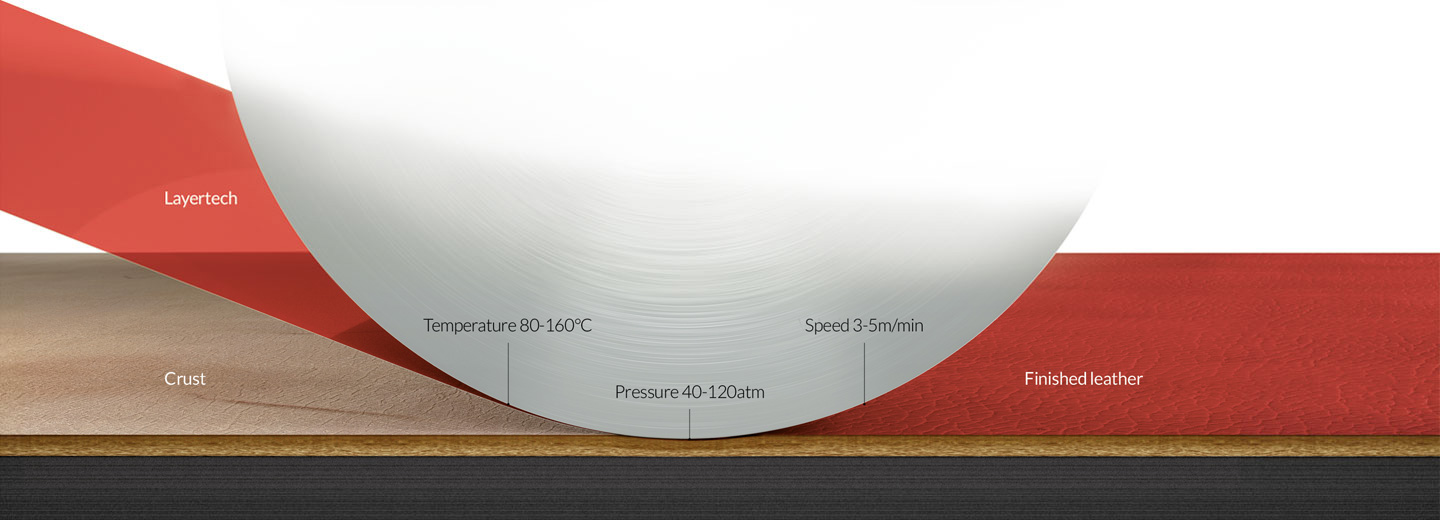

Each type of Layertech has its own standard parameters of application, but they can be modified, within a certain range, as per your needs. Layertech is applied with a hot roller machine and you can adjust the application variables, such as temperature, pressure and speed, according to the type of leather and to the final result you want to get.