Layertech > The finishing evolution > Technology

Unity is strength and it also makes the difference.

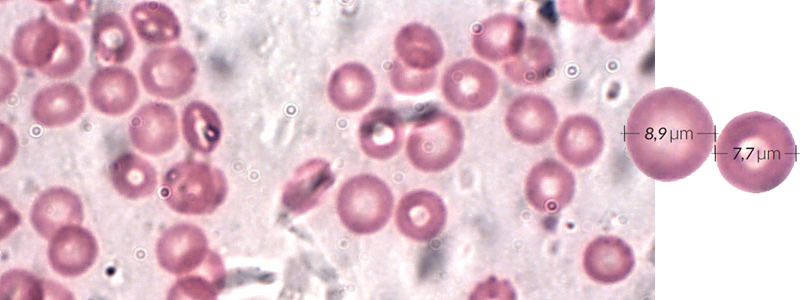

Layertech is a multi-layered composite of very thin polymeric gels (1-2 microns each approx.) with a low melting point. It consists of three main groups, each with a specific function and in turn, each group is made up of multiple layers. During the application process, the low temperature required for fusion enables the different layers which make up Layertech (from 3 to 10 layers in the standard range) to combine with each other and the leather thus creating an all-in-one where the thickness of the product is practically zero. The specific characteristics of the substances, the modularity of the composition and the irrelevant thickness potentially allow infinite combinations, where the only limit is your imagination.

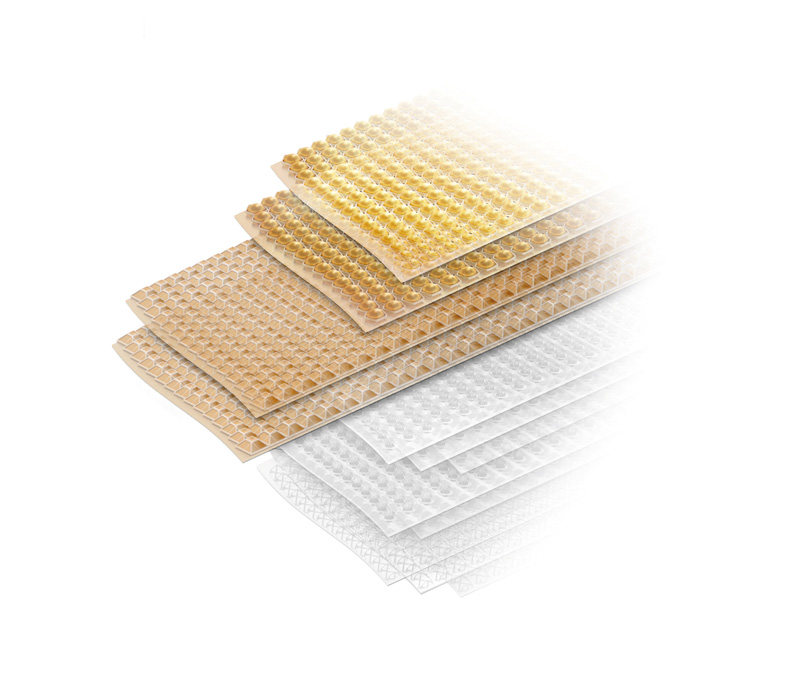

Layers of adhesive

The first group consists of special layers of adhesive substances with very high adhesion that on melting penetrate the leather (without altering its softness) and bind the upper layers permanently to the leather.

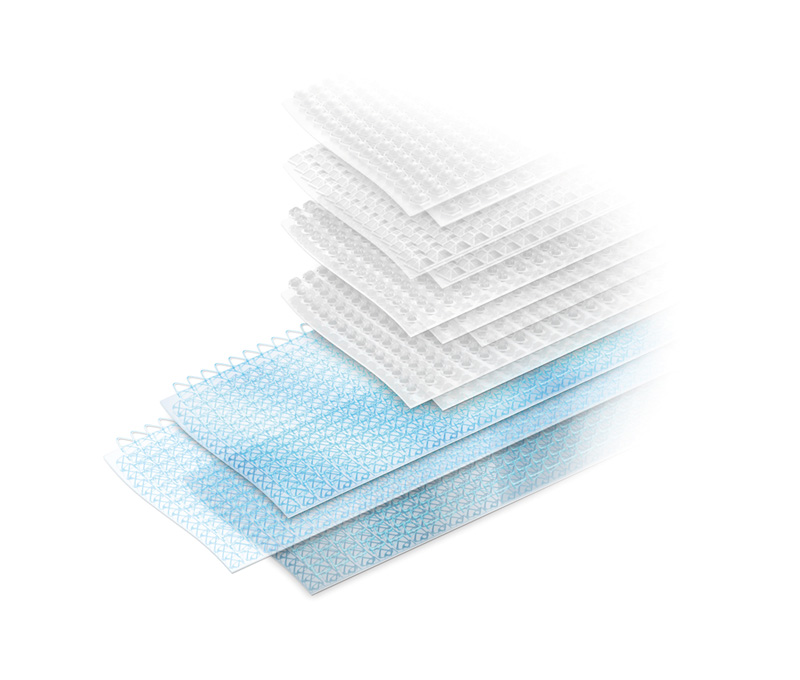

Layers of colorants

The middle group contains a variable number of layers of colorants (pigments and/or anilines) that are combined in such a way, so as to achieve specific degrees of transparency or covering, brightness and intensity.

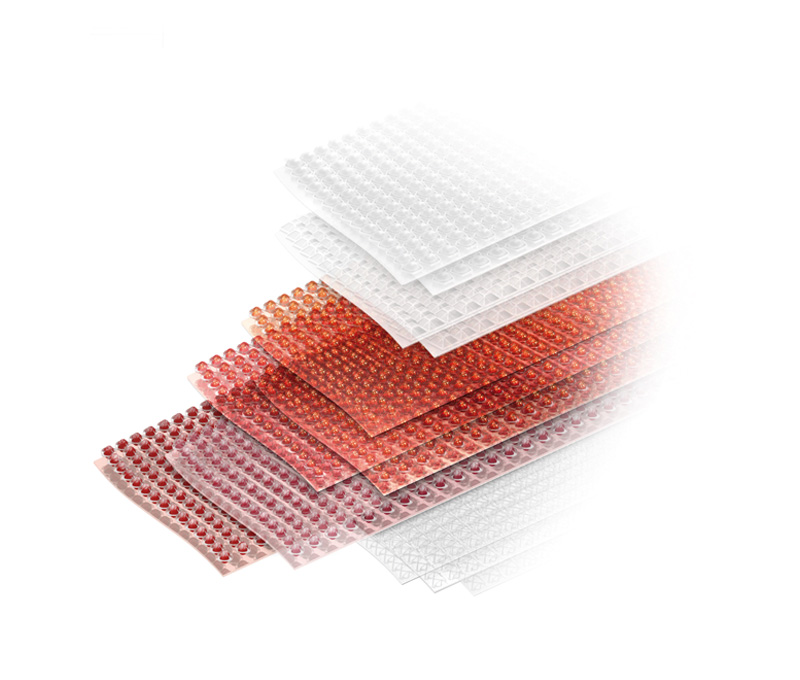

Strength and the hand

Finally, the surface group, which is also made up of different layers with particular characteristics, provides the strength and hand of the finishing.