Layertech > The finishing evolution > Vantaggi

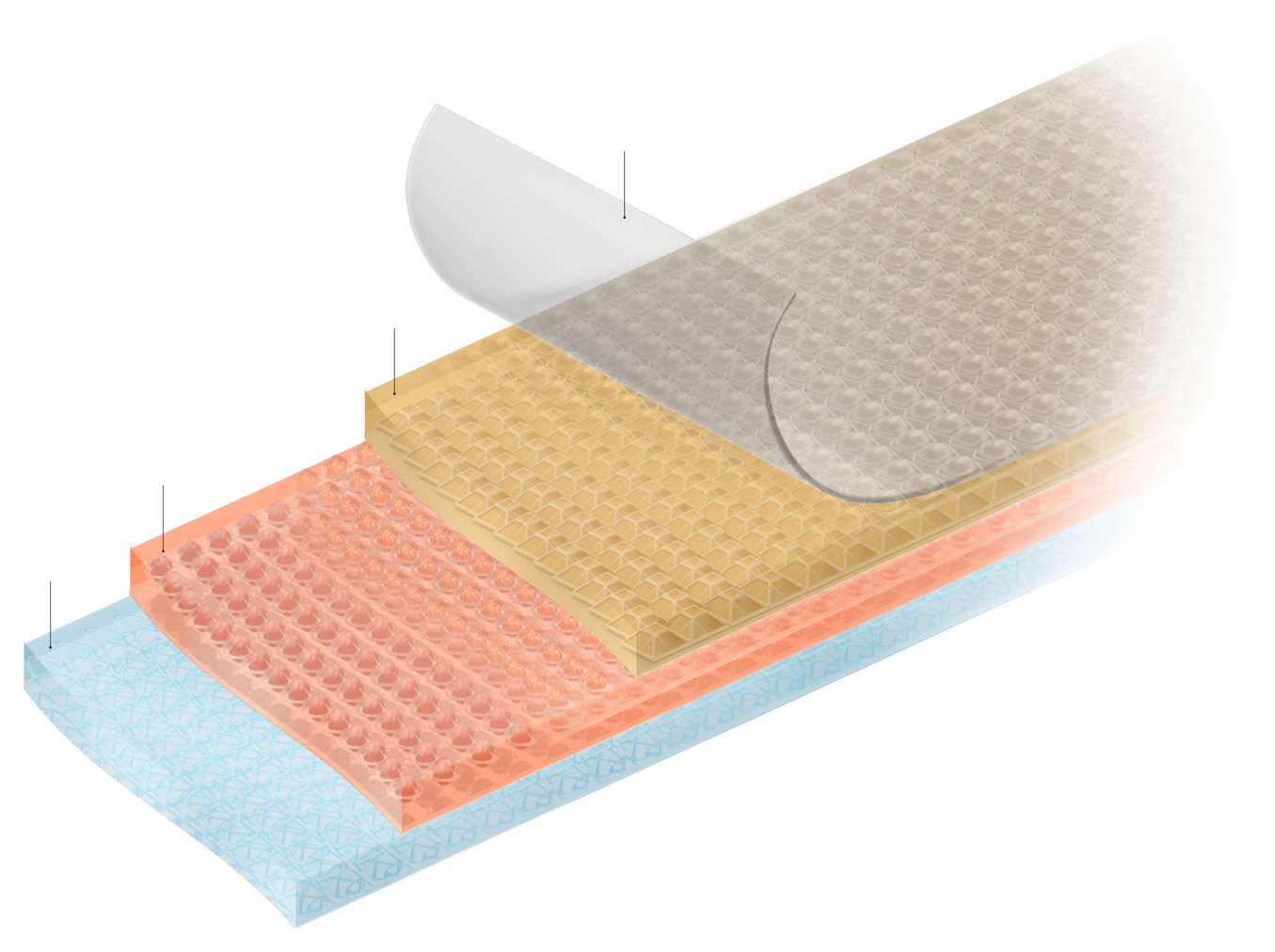

Layertech is the most efficient finishing technology available on the market.

Extreme simplicity of application, zero fumes and no water consumption, enormous time saving, significant reduction of production costs for an immediate and versatile result. These features make Layertech hyper-efficient and even unsurpassable in the case of split productions. Why settle for less when you can have more?